Reasons Why Qiming Casting Cone Crusher Liners Outlast the Competition

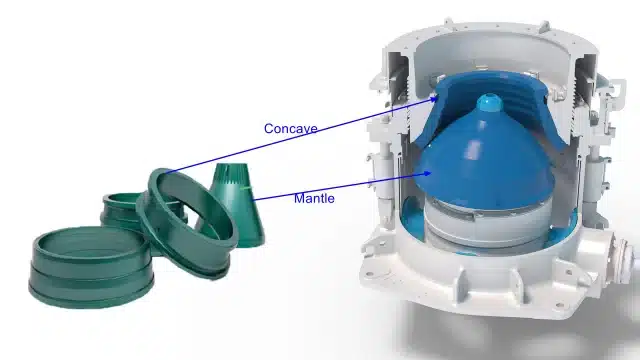

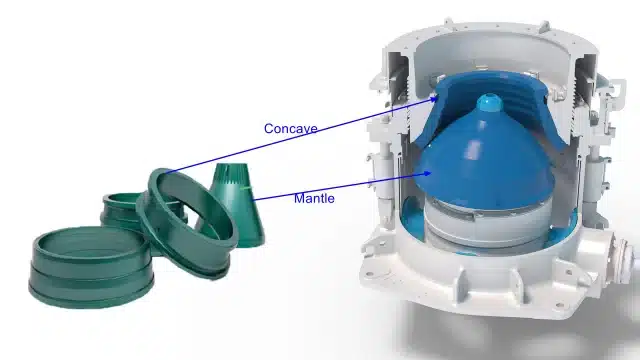

In the realm of heavy-duty industrial machinery like cone crushers, where wear and tear are inevitable, the quality of wear parts can make a significant difference in performance, efficiency, and overall cost-effectiveness.

At Qiming Casting, we take immense pride in our commitment to delivering top-quality wear-resistant solutions for the mining, quarrying, cement, coal, and metal recycling industries. Among our array of offerings, our cone crusher liners stand out as exemplars of durability, performance, and longevity.

In this article, we delve into the reasons why our cone crusher liners outlast the competition, offering unparalleled value to our customers.

Speciality of the Qiming Casting Cone Crusher Liners

1. Premium Materials Selection

One of the core elements that set our cone crusher liners apart is our meticulous selection of premium materials. We understand the demanding nature of crushing operations and the importance of using materials that can withstand extreme conditions. That’s why we offer liners made from high-quality manganese steel, micro-alloy steel, and titanium carbide.

Our manganese steel cone liners, available in grades Mn14, Mn18, and Mn22, are renowned for their exceptional durability and impact resistance. Whether it’s tackling abrasive materials or heavy-duty crushing tasks, our manganese steel liners deliver unmatched performance, ensuring prolonged operational life for your cone crushers.

For even greater resilience, our micro-alloy cone liners incorporate molybdenum nickel, enhancing their wear resistance and longevity. These liners are designed to endure the most rigorous applications, providing extended wear time compared to conventional manganese steel liners.

Moreover, our titanium carbide inlay cone liners are tailor-made for handling ultra-hard stones, offering superior wear life and reduced maintenance costs. With Qiming Casting, you can rest assured that our premium materials will exceed your expectations, enabling your cone crushers to operate at peak efficiency for longer durations.

2. Customization Options

We understand that every crushing application is unique, presenting its own set of challenges and requirements. That’s why we offer a wide range of patterns and materials, allowing for customization based on specific crusher types and working conditions.

Whether you’re dealing with abrasive materials, high-impact loads, or abrasive wear, we have the expertise to tailor our cone crusher liners to meet your exact needs.

Our diverse selection ensures that you can choose the most suitable liner design and material composition for your application, maximizing the performance and longevity of your cone crushers.

With Qiming Casting, you’re not limited to off-the-shelf solutions – we provide customized liners that optimize the efficiency and productivity of your crushing operations.

3. Rigorous Quality Assurance

At Qiming Casting, quality is ingrained in every aspect of our operations. From the selection of raw materials to the final inspection of finished products, we adhere to stringent quality control standards to ensure superior performance and reliability.

Our state-of-the-art facilities and professional production team are equipped to deliver precision-engineered cone crusher liners that meet the highest industry standards.

Furthermore, we provide complete product testing reports, giving you full transparency into the quality and performance of our liners. We believe in building trust through accountability, and our commitment to quality assurance is evident in every liner that bears the Qiming Casting name.

4. Proven Track Record

Over the years, Qiming Casting has earned a reputation for excellence in the field of wear-resistant solutions. Our cone crusher liners have been deployed in diverse applications around the globe, delivering exceptional results in terms of increased working life and operational efficiency. Countless satisfied customers testify to the effectiveness and durability of our liners, cementing our position as a trusted partner in the industry.

From small-scale operations to large-scale mining projects, our cone crusher liners have consistently outperformed the competition, providing unmatched value to our customers. When you choose Qiming Casting, you’re choosing a proven solution that stands the test of time.

5. Customer-Centric Approach

At the heart of our business philosophy is a commitment to customer satisfaction. We understand that our success is intrinsically linked to the success of our customers, and we go above and beyond to ensure their needs are met with excellence.

Whether it’s providing expert technical support, offering timely delivery, or implementing feedback for continuous improvement, we prioritize the needs of our customers at every step of the way.

Our dedicated team is always on hand to address any queries or concerns you may have, ensuring a seamless experience from initial inquiry to post-sales support. With Qiming Casting, you’re not just getting superior cone crusher liners – you’re getting a partner who is fully invested in your success.

Discover Unmatched Durability and Performance with Qiming Casting’s Cone Crusher Liners

Overall, the reasons why Qiming Casting Cone Crusher Liners outlast the competition are clear: premium materials selection, customization options, rigorous quality assurance, a proven track record, and a customer-centric approach.

When you choose Qiming Casting, you’re choosing excellence, reliability, and unparalleled value for your crushing operations. Experience the difference today and discover why we’re the preferred choice for wear-resistant solutions worldwide.

Leave a Reply